Is Acoustic Treatment a Fire Hazard?

The short answer is no.

Most acoustic and soundproofing products are designed to resist burning and prevent the spread of smoke and fire. However, not all materials function the same under intense heat, so it is important to understand the safety information and limits of each product.

Acoustic panels and treatments improve sound quality by reducing reverb and echoes within a space. This helps to reduce background noise and provide an ideal environment for recording studios, auditoriums, busy offices, or anywhere with a lot of conversations happening at once. Naturally, these are places where a lot of people are gathered, making safety the top priority. In case of an emergency or a fire, you want to make sure these areas are designed to prevent the spread of flames and that everyone can exit the building quickly. In this article we will take a closer look at the safety regulations involving acoustic treatments.

Required Fire Regulations

Materials used in soundproofing, such as acoustical fabric, foam, drywall, fiberglass, and others, are generally nonflammable. They are not considered to be a fire hazard, and some materials such as fiberglass are even used as fire-blocking agents. While these materials are typically inflammable, they do have their limits and may catch on fire or burn if subjected to high temperatures for an extended period of time.

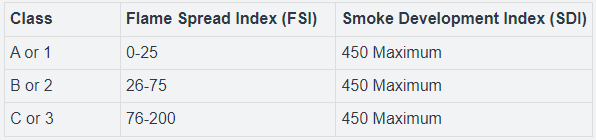

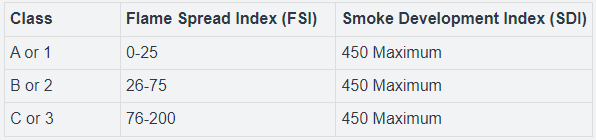

When it comes to building regulations, only Class A or Class 1 materials are approved to be used in public spaces as finishes for walls. The Class A (or Class 1) fire rating means that the object has superior fire protection, making it difficult for fires to spread across the object and producing very little smoke when burned. The fire rating is calculated based on the ASTM E 84, a testing method to determine the surface-burning characteristics of materials. This is used to categorize how quickly fire can spread across a surface and the amount of smoke it creates. Some acoustic panels and products have a Class 1 rating, meaning they are approved for use in highly public areas. Class B or C materials may be used in some areas with low occupancy and are subject to local building regulations. All Class A,B and C materials must have a smoke development index (SDI) of less than 450. This means that the material emits a low concentration of smoke as it burns.

FireFlex - Fireproof Acoustic Foam

If you are looking for highly rated fireproof acoustic wall panels or baffles, we recommend FireFlex. FireFlex is a line of fire-rated noise absorbers made from an open-cell melamine foam. These products are capable of resisting heat up to 482°F and constant temperatures of 320°F. FireFlex acoustic foams have a rating of 20 flame spread index (FSI) and 75 SDI, making them ideal for buildings requiring Class 1 materials. These panels boast some of the lowest flame spread values compared to other acoustic panels. FireFlex acoustic foams are available in Wedges, Pyramids, Hanging Baffles, and FabTec- fabric-covered wall panels. FireFlex is engineered for environments where temperatures are high, sparks or other hot materials may fly, large numbers of people congregate, or high-technology products are used. FireFlex is made from a special lightweight open-cell acoustic melamine foam. The internal material structure consists of a low-density, spacious, flexible web, offering a high noise reduction class (NRC) in addition to its superior fire-resistant qualities.

|